Petrarch and Steni Factory Tours 2022

It was a real privilege to welcome Omnis

It was a real privilege to welcome Omnis and key partners to the UK. Inviting our partners to the factory to learn more about our products helps everyone understand the manufacturing process highlighting the breadth of design and functional capabilities of Petrarch. We thoroughly enjoyed creating and customizing panels and letting Omnis reps get hands-on in the production process. The entire visit was highly successful from start to finish. We look forward to welcoming you again in the not-too-distant future!

It was very fruitful to meet

It was a real pleasure to meet the group from Omnis here at the Steni factory and project sites in Norway. It has been very fruitful to meet with the management, architect, and rep. We have learned a lot about the possibilities and the room for improvement during these very pleasant days with this great group.

Omnis hosted representative Divya Gupta with CLADDCO, and architect Brad Norvell with CPL Architects for a special trip to the UK and Norway to tour Petrarch and Steni factories. The warm reception was matched by the educational “show-and-tell” of factory operations.

The objective of the tours was to help reinforce material selection, to inform the best possible design decisions, and to facilitate constructing projects in the most efficient manner to help ensure the best possible end results and within budget.

Aesthetics

- Color – Understanding the range of color options, customization (color matching)

- Finishes/texture – Understanding the range of finishes

- Petrarch: Smooth, Smooth Matte, Riven Smooth, Riven Matte, Honed

- Steni Color: (Gloss, half matte, matte); Nature (Fine Micro, Fine, Medium, Large)

- Customization – Routing, Printing (Steni Vision), Perforations

Designability & Constructibility

- Joint options

- Corner options (formed corners, fused corners)

- Unsupported returns (Petrarch)

- Radius

- Panels sizes / optimization

- Fabrications/cutting in the field

Durability, Sustainability, and Expected Life

- Easy to clean and maintain

- Impact-resistance

- Recycled content

- Options to re-use the material

- Steni EPD

The group also visited Petrarch projects in London and Steni projects in Norway.

See Our Tour Diary

Beau Preston, President Omnis + Brad Norvell, CPL Architects with Graham Tuff, Petrarch Quality, Training and Improvements Manager

Creating corners, rainscreen attachment demonstrations, custom Petrarch mementos … Graham Tuff, Petrarch Quality, Training, and Improvements Manager spent the day demonstrating the versatility of Petrarch Panels.

Seeing the Petrarch factory and demonstrations by Graham reinforced our decsion to use Petrarch Panels on a current project. Taking part and physically implementing the installation of the panels on a mock-up was important. To a degree I grew up in a construction environment and there is no better way to learn about a material or system than by physically understanding their limitations and opportunities.

The current project using the Petrach panels came about through an exploration of the final material selections. In the early stage of design, the intent was to select a material was more natural in texture and color. The material also needed to be durable and withstand a level of interaction at the human scale. We explored terracotta and other materials. In the end, the Petrach Composite Stone panels gave us a wide range of natural colors that we could easily coordinate with the other building materials and meet the desired design intent.

Corner conditions/option are a big deal for me. Seeing those in person was huge and gaining a better understanding of the efforts required in the factory to accommodate those conditions. Similarly seeing this helped me to know how to better prepare conversations for future pre-installation and coordination meetings to ensure both the design and manufactured intent can be met.

Brad Norvell, CPL Architects.

Omnis representative Divya Gupta, President of CLADDCO, found the Petrarch tour equally as valuable.

I loved Graham’s demonstration of face fixed, adhesive secret fix and mechanical secret fix. And seeing Graham create a custom CLADDCO Petrarch plate as a memento was really special.

Divya Gupta, CLADDCO

Petrarch Projects Tour

- Filmworks

- Natural History Museum

- Holiday Inn Express

The Filmworks

This impressive building was remodeled from the historic Empire Cinema, preserving the stunning art deco façade. The new mixed-used building provides over 200 contemporary homes, an eight-screen Picturehouse cinema, and a central piazza surrounded by a high-quality mix of restaurants, coffee shops, and leisure facilities. The exterior is clad in Petrarch Panels in Alabaster Smooth, 10mm Secret Fixed.

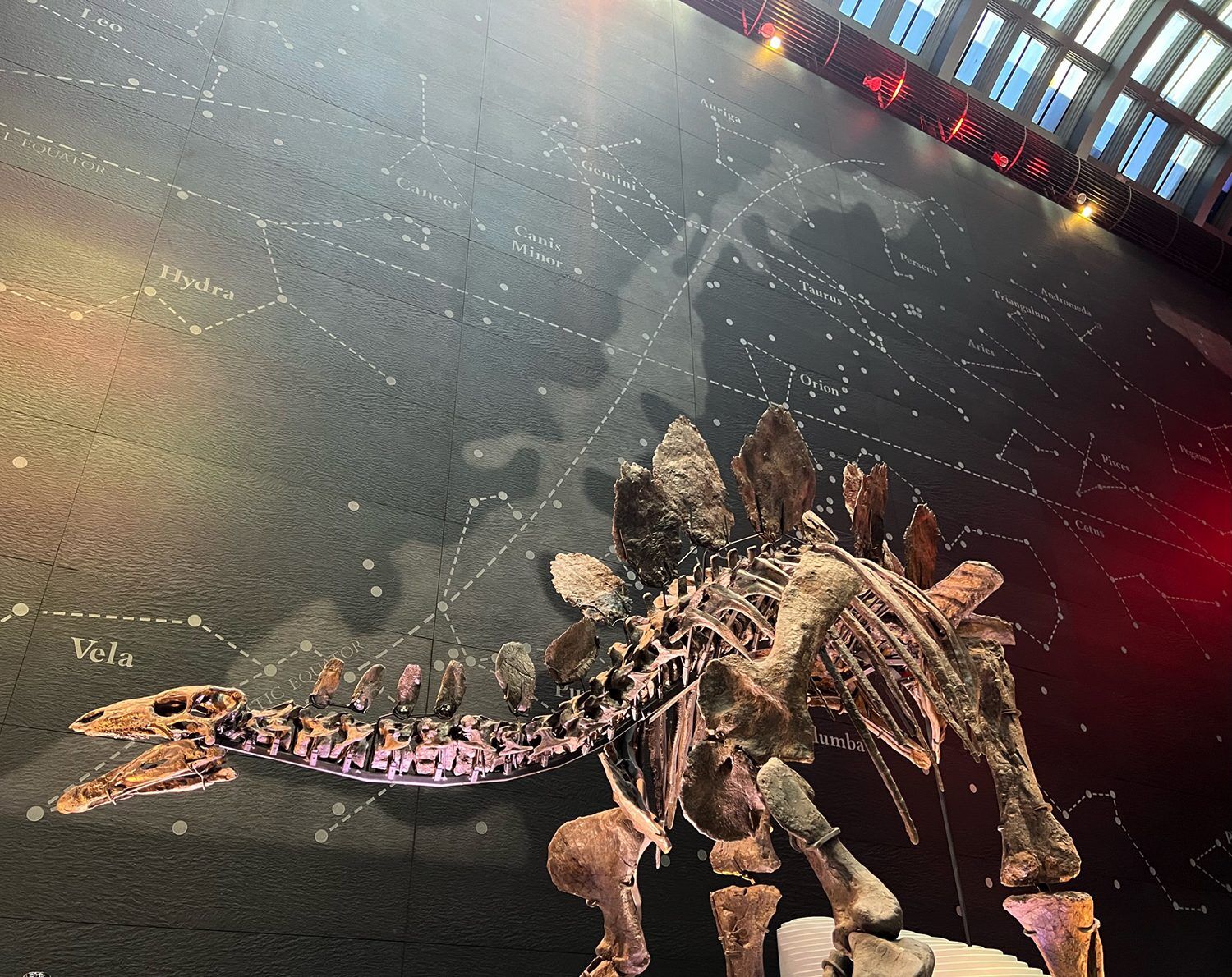

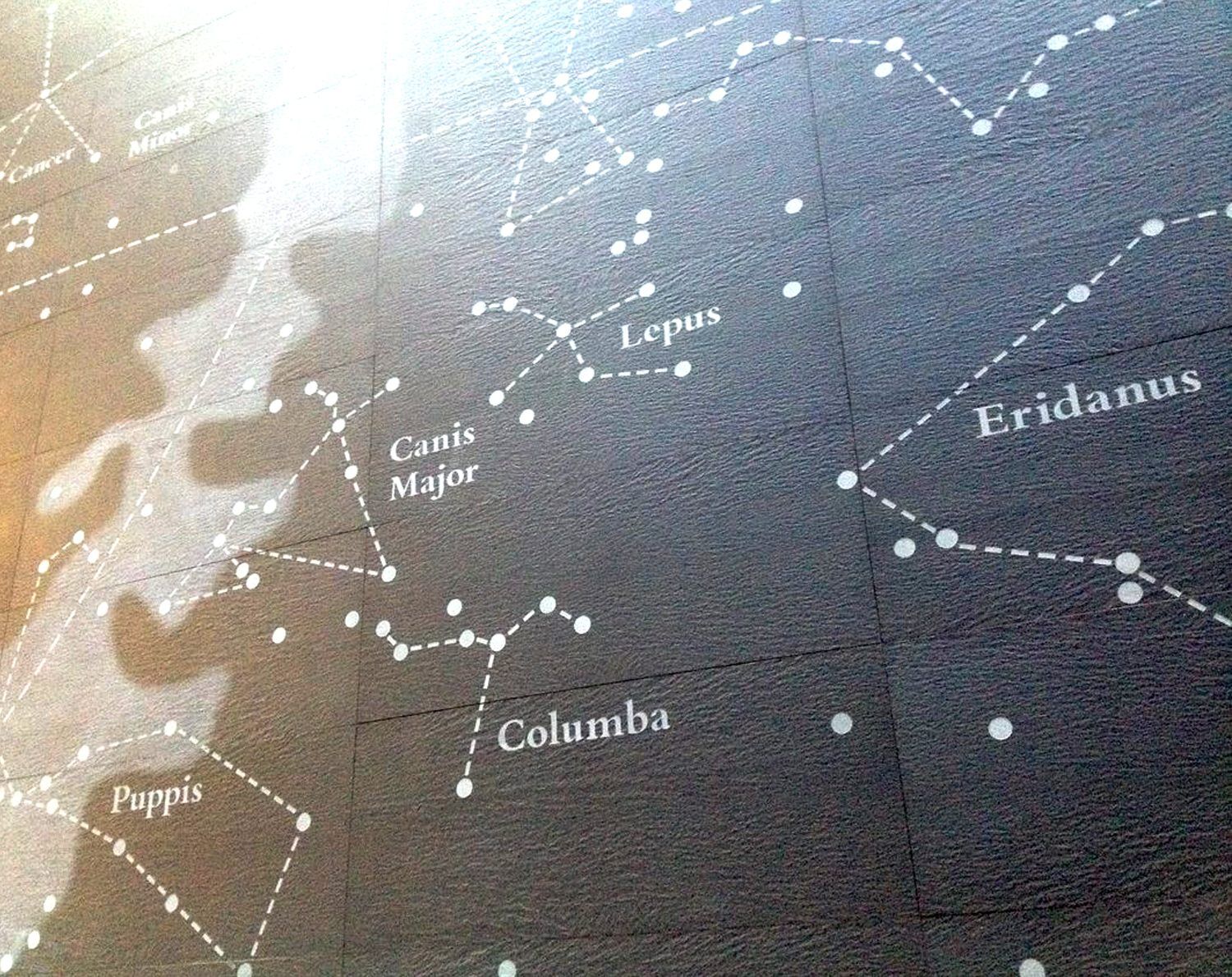

Natural History Museum

In 1996, the former Geology Museum in South Kensington was transformed into the Natural History Museum’s Earth Galleries. The atrium of the museum is clad in Petrarch Riven, Graphite. The Petrarch Composite Stone Panels were sent to an artist who etched the constellation design into the panels. Some panels were lightly etched, others were painted to give different depths and contrast.

Holiday Inn Express

Located in Southwark, London, UK, the Holiday Inn Express was developed in 2012 as an inclusive design hotel. Architects Dexter Moren Associates introduced a number of systems to reduce the building’s carbon footprint, such as the rainwater harvesting system which provides water for irrigation to the green/living wall on the rear external elevation and the roof has an array of photovoltaic cells. The Petrarch Composite Stone Panels in Dorset, Smooth Matte have withstood the test of time, including the panels installed to grade.

Brad Norvell, CPL Architects with Thor Rikard Odberg, Steni

The Steni production plant is a little under two hours from Oslo in Norway. Steni’s plant is state-of-the-art, allowing the company to continually innovate.

Similar to the Petrach panels, the corner options are important to me. For instance, I recently used the Steni Composite Stone Colour panel on a project that had originally been slated to use metal panels. The design intent was a slick automotive finish with consistent color in addition to the crisp outside bent corners achieved with metal panels. A large concern we had with the metal panels was durability and that a large portion of the panels would have daily interaction with people, chairs, and other objects that could easily scratch and dent the panels.

In working with Omnis Panels for an alternative product solution our team soon realized that we could meet the full design intent by using the Steni Composite Stone Colour panels. The consistent color and desired gloss could be achieved as well as the crisp outside corners through the detailing of a premanufactured corner shape. In addition, the Steni Panels provided a high level of impact resistance that reduced concerns of damage and potential ongoing maintenance for the owner.

Gaining a better understanding of the standard manufactured panel size as it relates to efficiently using the product is key. As the building design develops, the team should be mindful of the efficiencies of particular products such as Steni and likely work towards developing a final design that maximizes the panel and reduces waste.

Brad Norvell, CPL Architects

We saw first-hand Steni’s extremely innovated manufacturing process. It was exciting to see the new products they are developing.

Beau Preston, Omnis

Steni Projects Tour

- Kristian Augusts Gate 13

- Ishall Ice Arena

Kristian Augusts Gate 13

It was great to see this award-winning project in person. The Steni Composite Stone panels from a 35-year-old housing association were recycled and repurposed for this 1950’s building in Oslo threatened with demolition.

Ishall Ice Arena

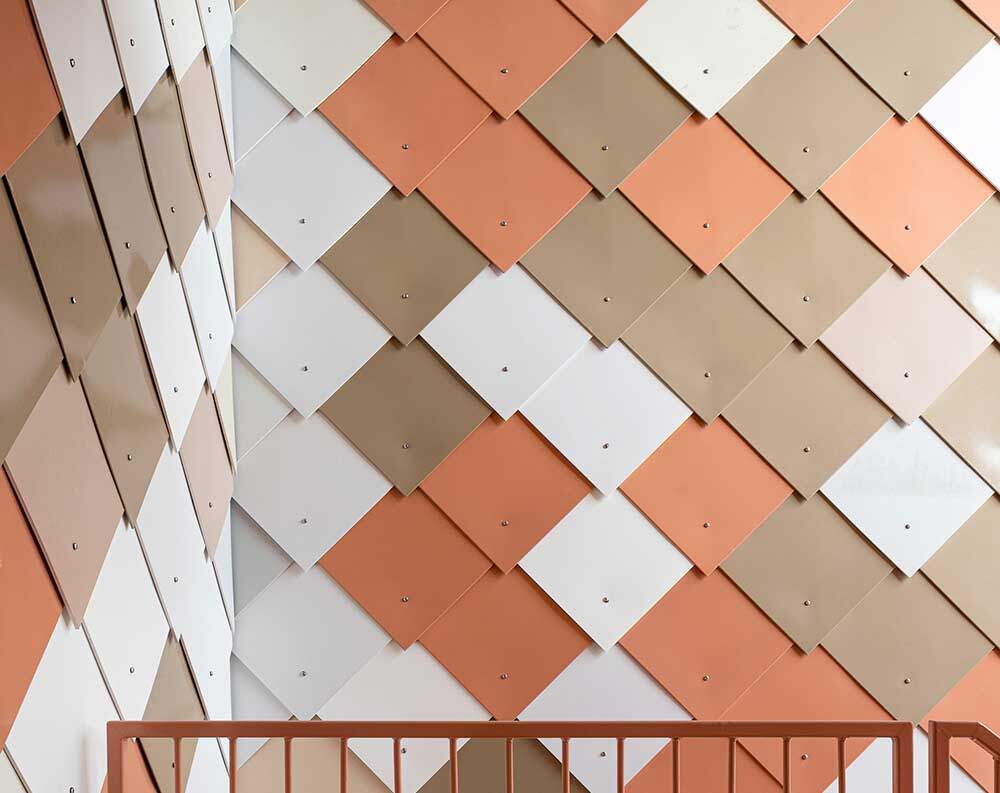

Ishall is a gorgeous example of Steni Vision custom panels.

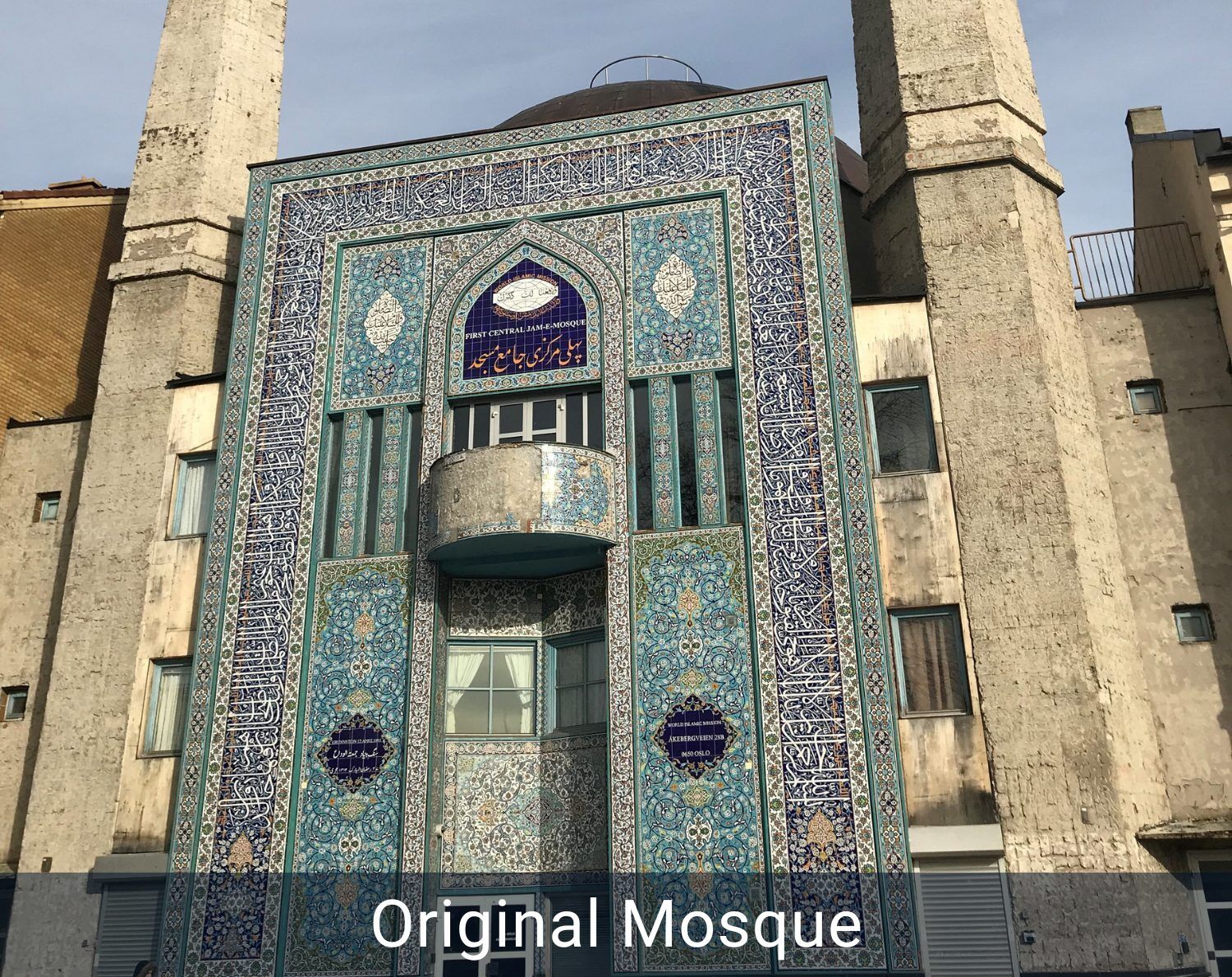

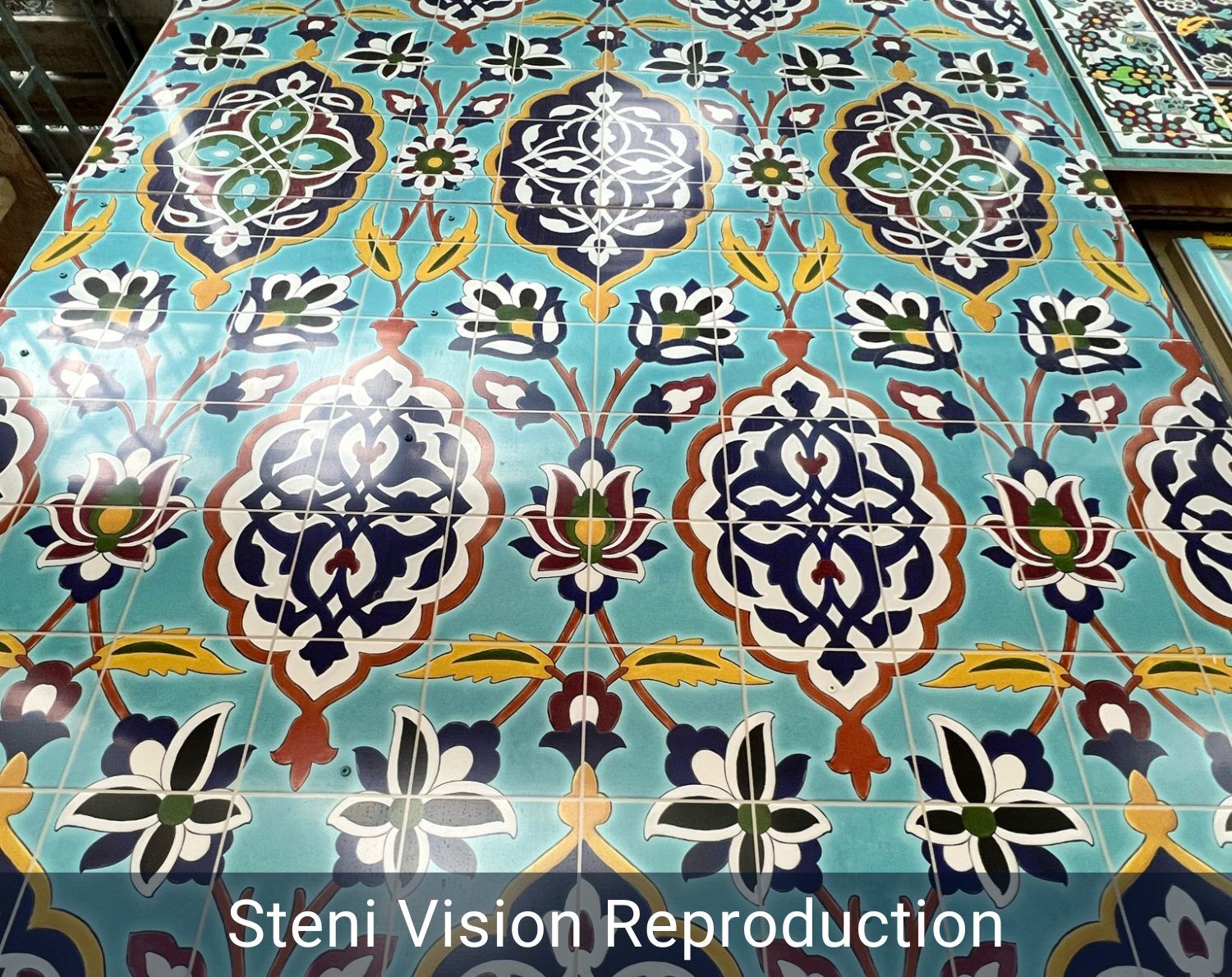

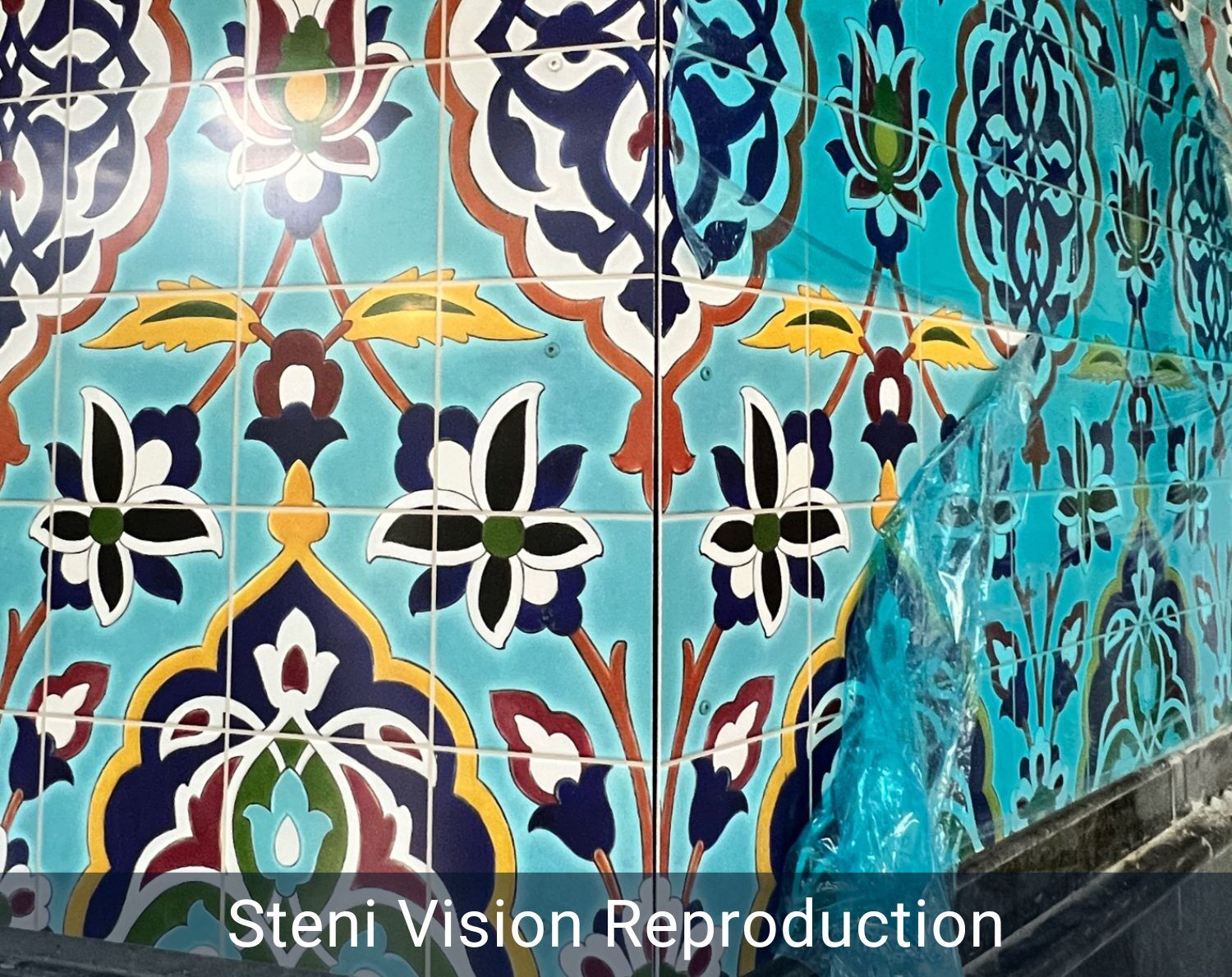

Steni Projects Tour – The Mosque

Future Award-Winning Steni Project

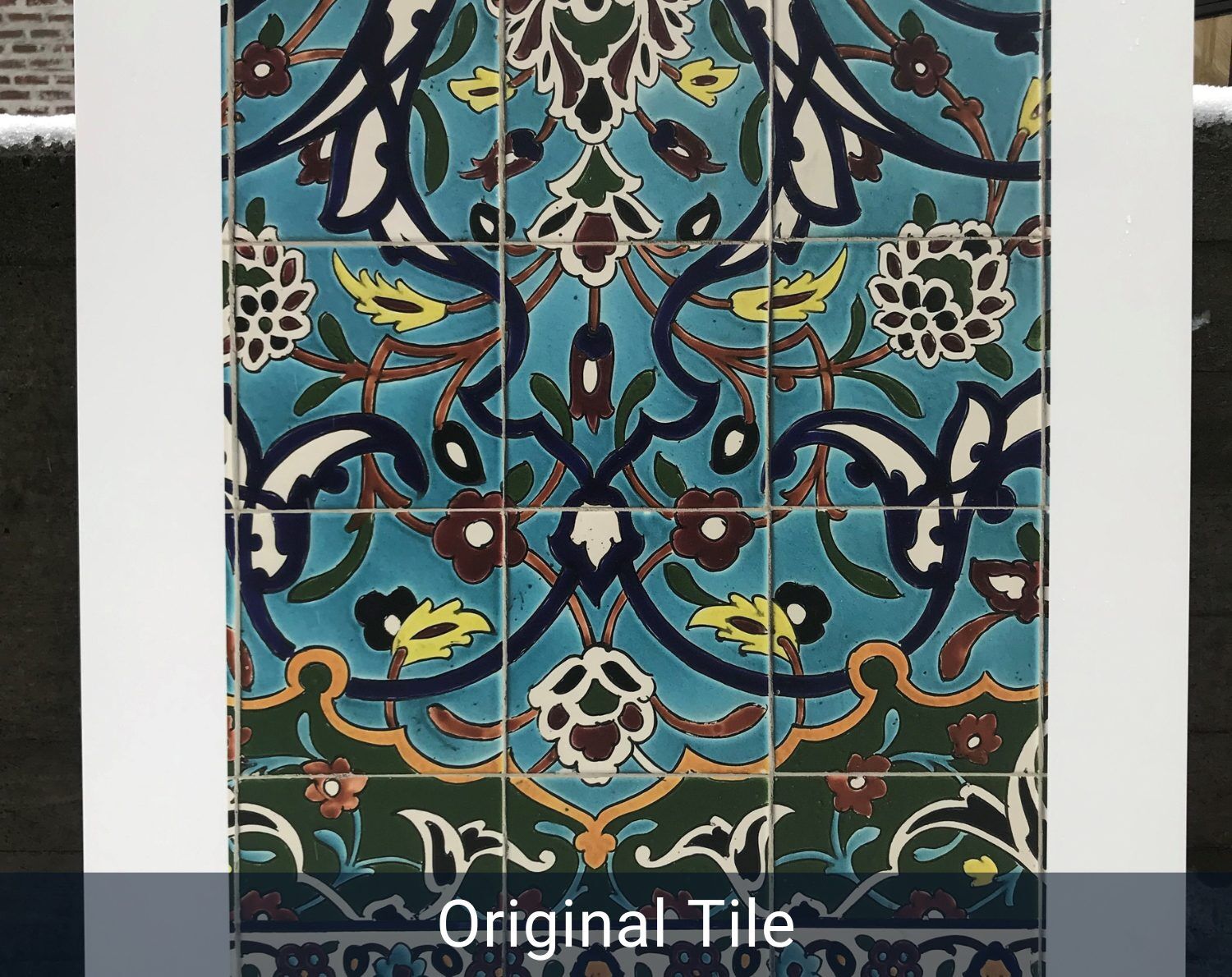

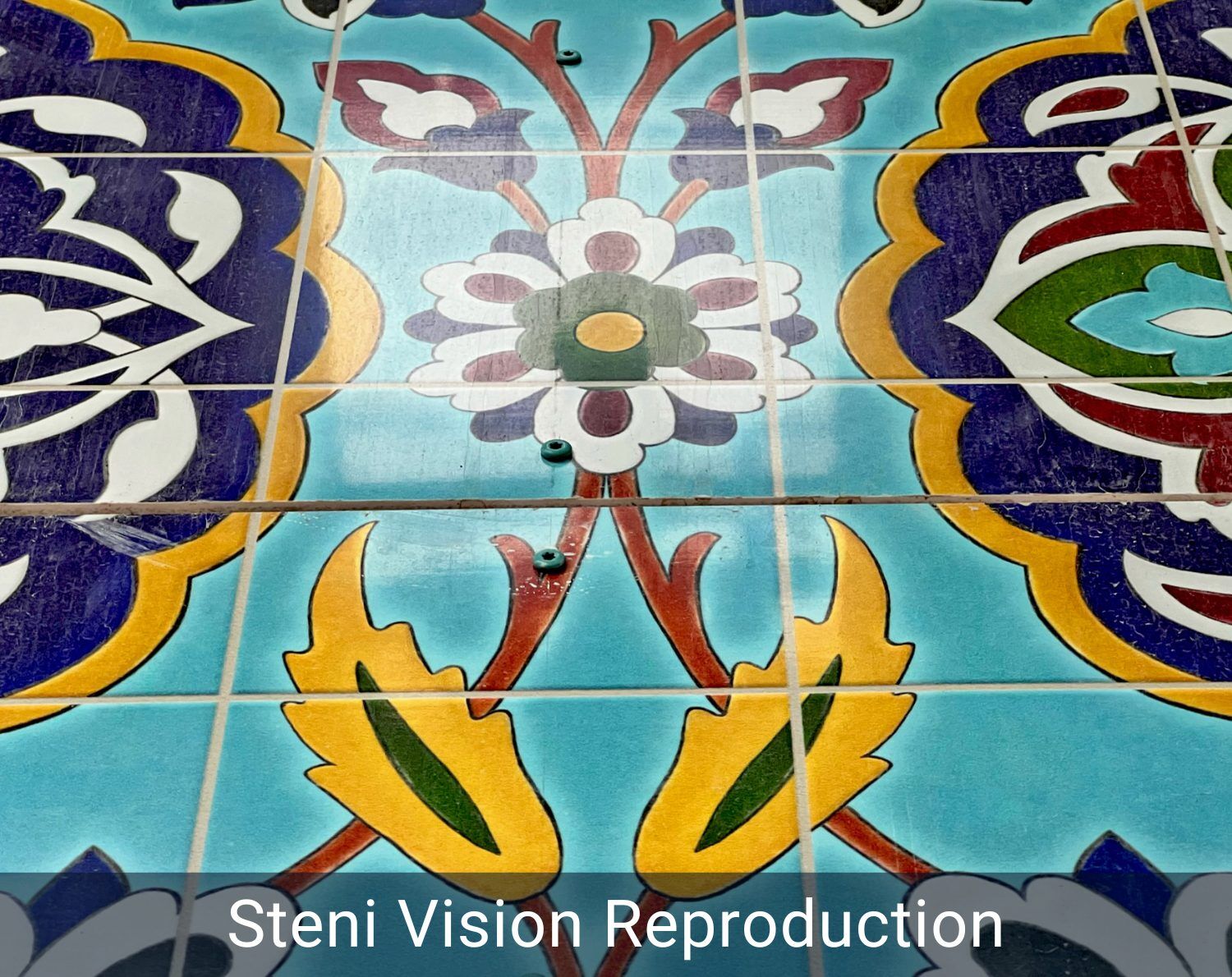

In February 2019 the owner of a badly aging mosque contacted Steni to reclad the building. The building originally had ceramic tiles on the exterior which had fallen off or were taken down. This challenging project involved scanning 400 different ceramic panels on this façade, every panel unique in design. These images were used by Steni to digitally recreate the tiles and match them perfectly.

This Steni remodel is an exceptional example of what Steni can do with customized composite stone panels. See the case study here>