K-Form PVC Concrete Formwork System

Work 4X Faster. Save Time, Money, and Labor

K-Form PVC concrete formwork system is a patented, lightweight, 100% recycled PVC system that works up to four times faster than traditional steel and timber concrete formwork systems. The versatile, innovative, and sustainable PVC concrete form system saves time, money, and labor while enhancing the aesthetic finish of the concrete slab.

Pour more concrete: Just set out your grid and pour bay after bay, without stopping.

Pour more concrete: Just set out your grid and pour bay after bay, without stopping.- Acts an expansion and contraction joint.

- Does not puncture the vapor barrier.

- Unlike foam or fiber expansion joint filler material, K-Form is resistant to gasoline, diesel, and oil making it suitable for forming concrete slabs at petroleum sites, industrial sites, and agricultural applications.

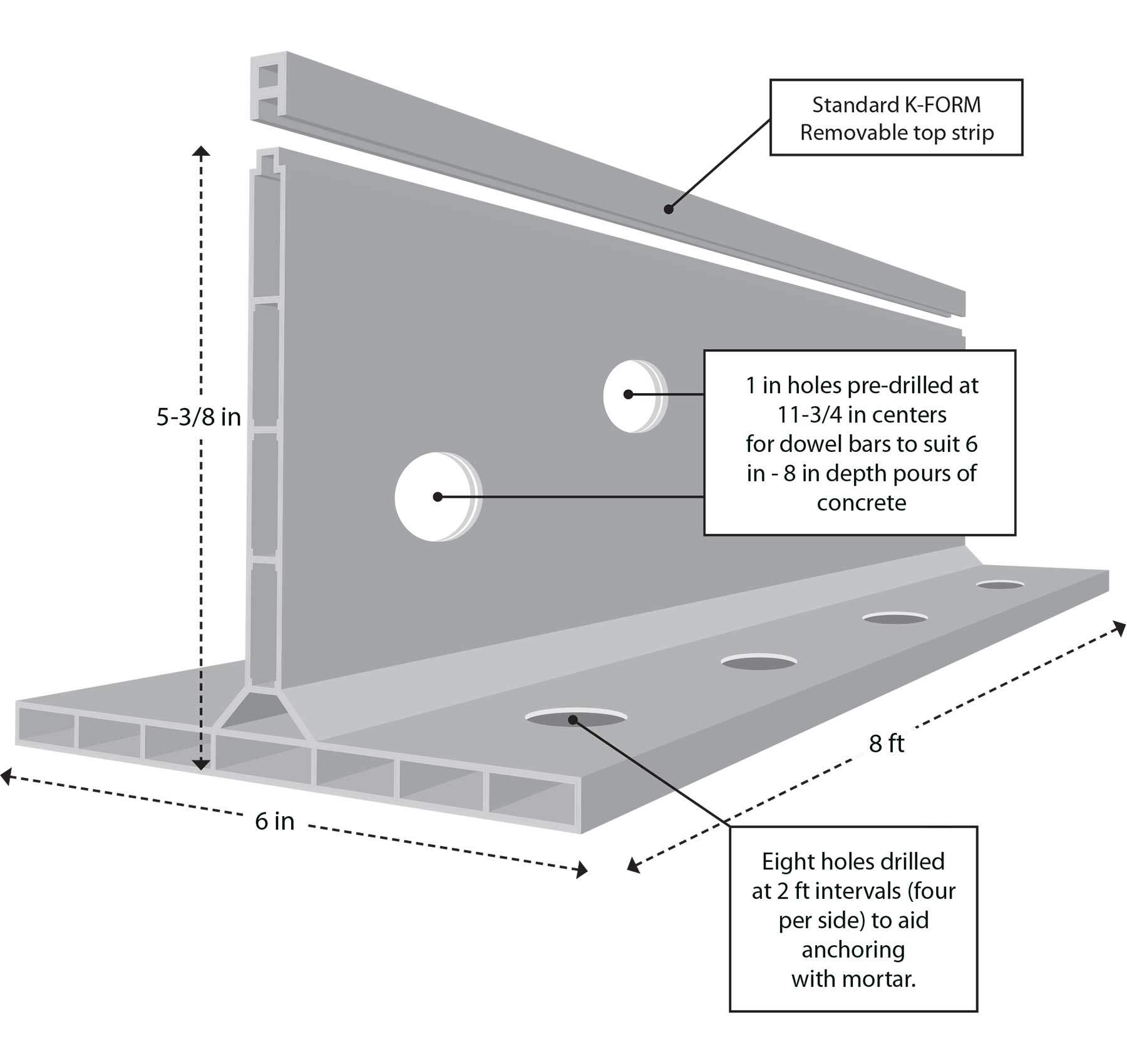

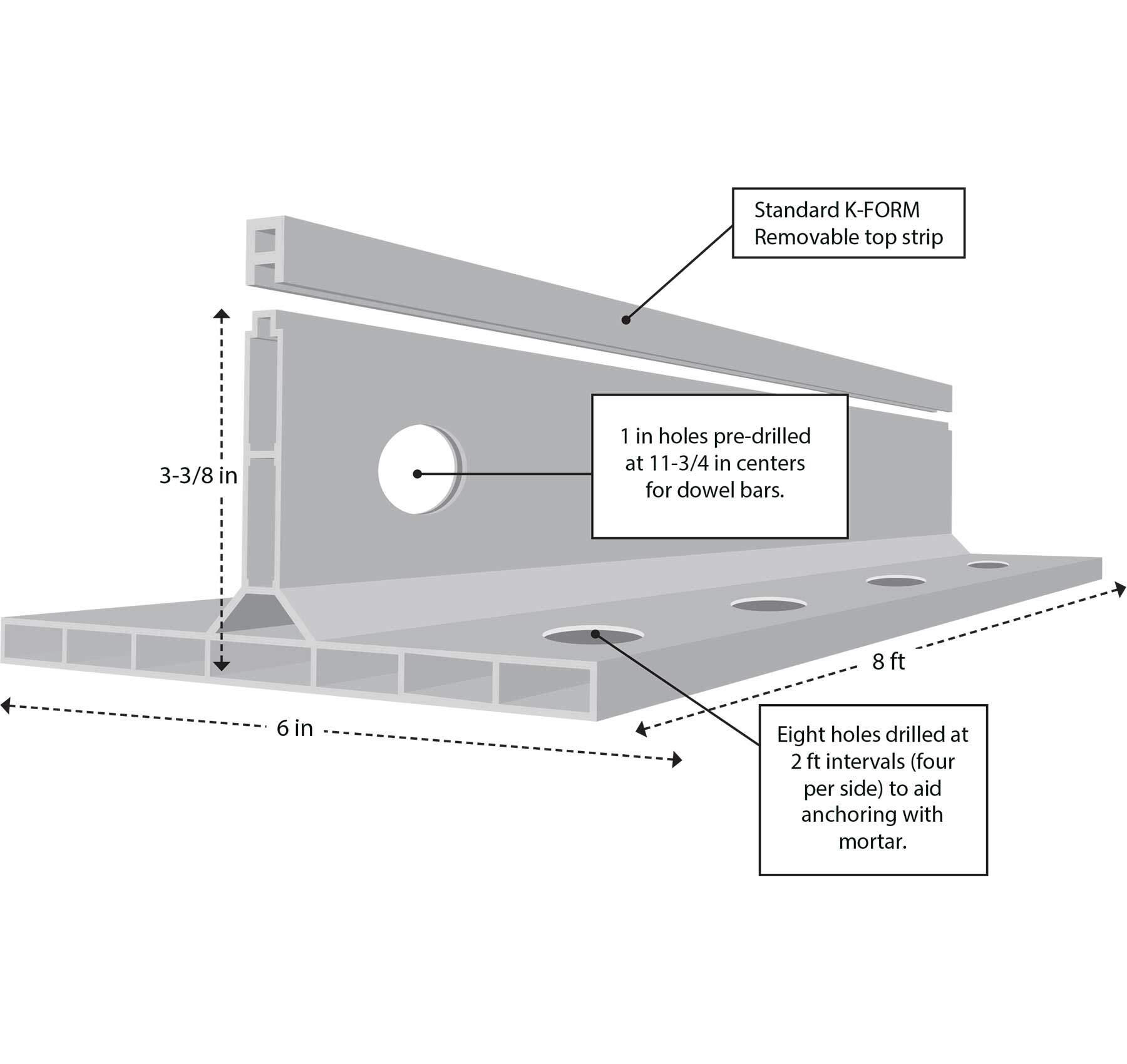

- The bottom base of K-Form acts like a lever when the concrete is placed on top of the bottom flange. It will not shift side to side or tip over. K-Form stays in place without stakes or backfilling.

- All types of power screeds are suitable to use with K-Form, (Roller screeds, Vibro-Strikes, Twin Beams, etc.)

- K-Form is strong enough to handle all types of leveling equipment.

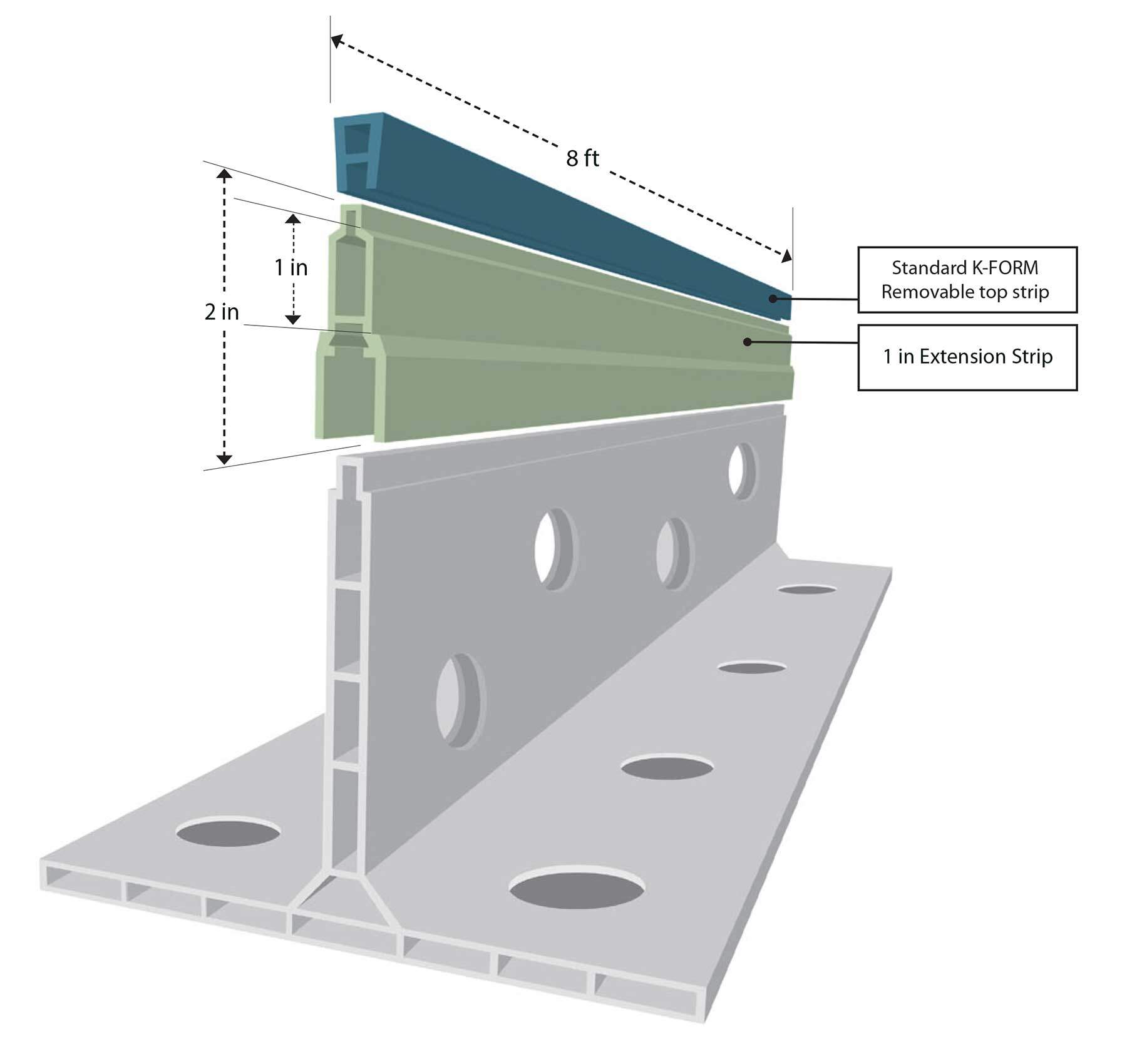

- The removable top strip eliminates the need to wet diamond-cut joints for sealant.

- No need to remove the shuttering after pouring concrete.