SikaTack® Panel Adhesive Rainscreen Attachment System

SikaTack® Adhesive Rainscreen Panel Attachment System is a high-performance adhesive system for invisible, durable fixation of rainscreen panels. SikaTack® Panel System is suitable for fixing composite, ceramic, high-pressure laminate, and many metal and powder-coated cladding. SikaTack® works ideally with our lightweight, durable Steni and Petrarch composite stone rainscreen panels.

The benefits of the SikaTack® Panel System

- SikaTack® Panel System costs up to 40% less compared to hidden mechanical fixation.

- Fast installation makes SikaTack® Panel System extremely cost-effective.

- The strength of the SikaTack® Panel System system absorbs dynamic and static stresses, as well as elevated façade temperatures.

- The adhesive layer prevents corrosion caused by screws.

- Elastic bonding provides uniform tension over the whole panel, preventing deflection of panels.

- Aesthetically pleasing – No screws or rivets are used during installation.

Sika® Aktivator-205 is a solvent-based colorless clear adhesion promoter, which reacts with moisture and deposits active groups on the substrate. These groups act as a link between substrates and primers or sealants/adhesives. Sika® Aktivator-205 is designed for the treatment of bond faces prior to the application of Sikaflex® and Sikasil® adhesives and sealants.

Sika® Aktivator-205 is a solvent-based colorless clear adhesion promoter, which reacts with moisture and deposits active groups on the substrate. These groups act as a link between substrates and primers or sealants/adhesives. Sika® Aktivator-205 is designed for the treatment of bond faces prior to the application of Sikaflex® and Sikasil® adhesives and sealants.

- Enhanced adhesion on various substrates

- Short flash-off time

- Easy to use

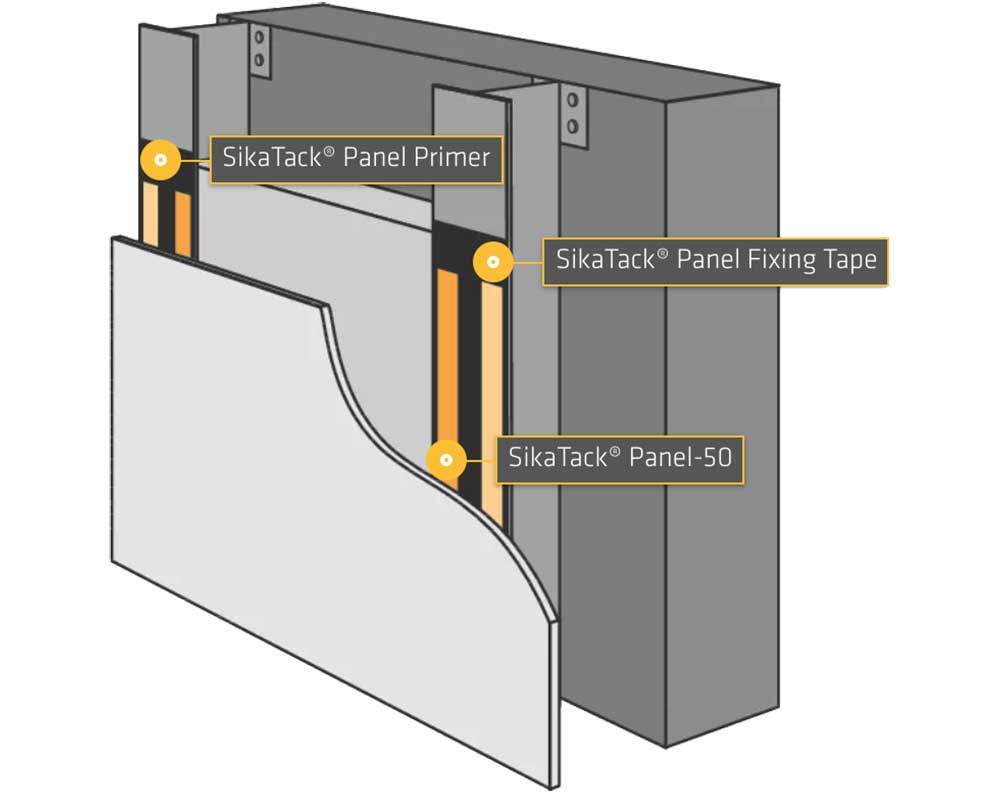

SikaTack® Panel Primer is a solvent-based black primer, which reacts with moisture and forms a thin layer. This layer acts as a link between substrates and adhesives. SikaTack® Panel Primer is specifically formulated for the treatment of bond faces prior to application of SikaTack® Panel adhesives. The SikaTack® Panel Primer is part of a system for the economic, concealed fixing of ventilated façades.

is a solvent-based black primer, which reacts with moisture and forms a thin layer. This layer acts as a link between substrates and adhesives. SikaTack® Panel Primer is specifically formulated for the treatment of bond faces prior to application of SikaTack® Panel adhesives. The SikaTack® Panel Primer is part of a system for the economic, concealed fixing of ventilated façades.

SikaTack® Panel Fixing Tape is a closed-cell polyethylene spacer tape for the initial fixation of rainscreen facade panels during the curing of SikaTack® Panel adhesive. It has a pressure-sensitive adhesive on both sides and offers very high peel and shear properties.

is a closed-cell polyethylene spacer tape for the initial fixation of rainscreen facade panels during the curing of SikaTack® Panel adhesive. It has a pressure-sensitive adhesive on both sides and offers very high peel and shear properties.

- Very high initial tack

- Bonds well to a wide variety of substrates

- Fast and easy to apply

SikaTack® Panel 50 is a non-sag, 1-component silicone of paste-like consistency for structural joints in Rainscreen facades. It cures on exposure to atmospheric humidity to form a durable elastomer.

SikaTack® Panel 50 is a non-sag, 1-component silicone of paste-like consistency for structural joints in Rainscreen facades. It cures on exposure to atmospheric humidity to form a durable elastomer.

- Elastic fixing system, vibration, and movement-absorbing

- Provides creative opportunities for facade design

- Withstands high dynamic and static stresses, and elevated facade temperatures

-

SikaTack®

SikaTack® Panel Rainscreen Attachment System Installation

Read → SikaTack Panel System General Guidelines

Mark precisely where the first panel must be bonded on the substructure, or use a reference fixed on the substructure. Make notes for your record with all relevant information. Ambient Temperature 40 – 95°F

- The surface to be bonded must be clean, dry and free from dirt. Use an 80 grit abrasive pad on the paned and the substructure. Ask us for specific advice on pre-treatment steps.

- Remove dust with a lint-free paper towel.

- Activate the bond faces with Sika® Aktivator-205. Use a clean, lint free paper towel and wipe in one direction only (dirty cloths must be replaced).

- Shake SikaTack® Panel Primer thoroughly. Apply one thin coat of SikaTack® Panel Primer uniformly over the whole surface with a felt pad. Allow a flash-off time of at least 30 minutes.

- Apply SikaTack® Panel Tape over the whole length of the vertical sections and parallel to the edges. Do not pull off the protective foil at this time.

- Apply SikaTack® Panel-50 in a triangular bead by using a triangular nozzle (width 8 mm, height 10 mm) with at least 5 mm gap to the fixing tape and to the side of the batten.

- Remove the protective foil on the SikaTack® Panel Tape.

- Place the cladding panel in the required position first, without the panel touching the fixing tape. Then, press it firmly until it touches the SikaTack® Panel Tape.

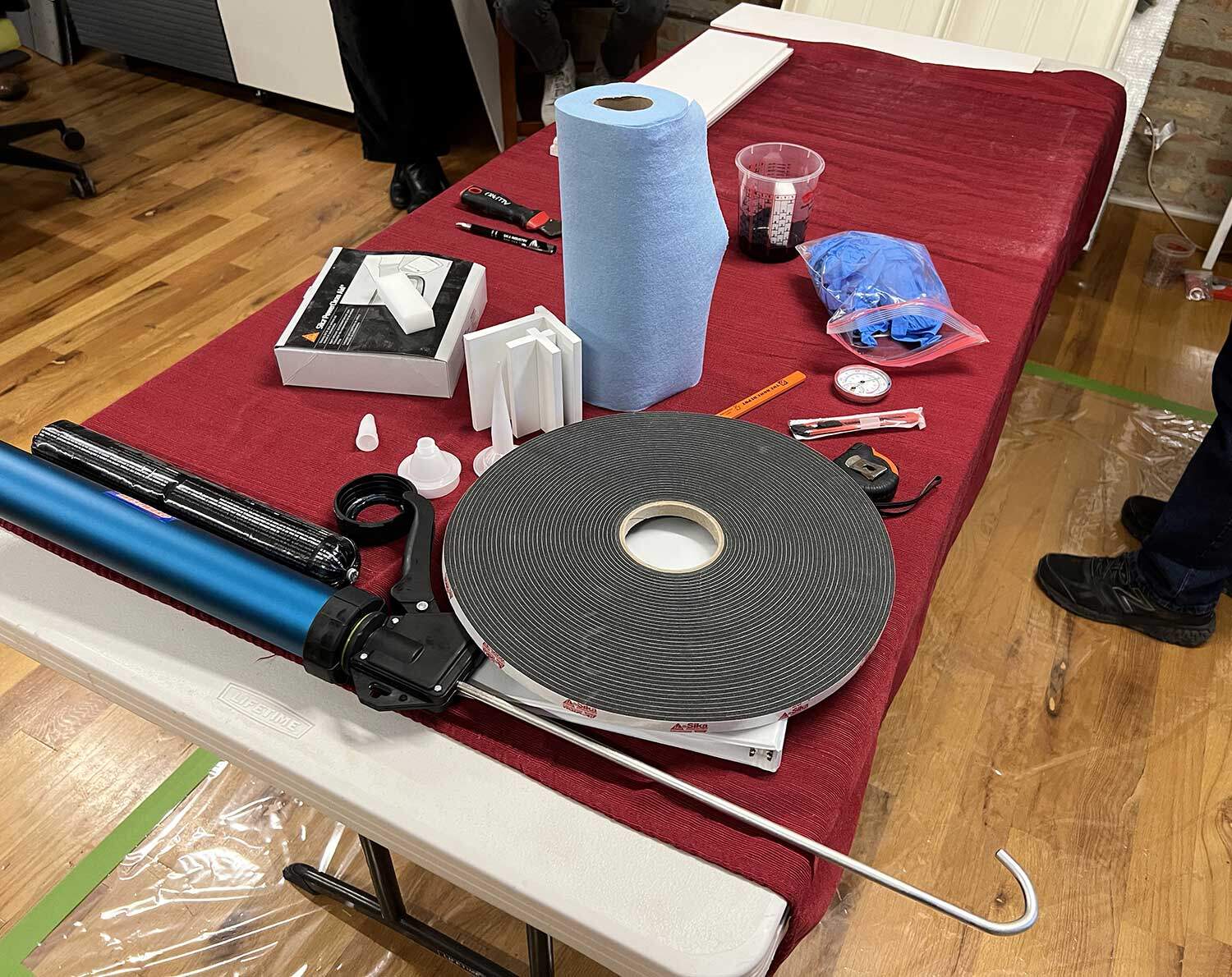

The SikaTack® Panel System includes:

- SikaTack® Panel-50

- SikaTack® Panel Primer

- Sika® Aktivator-205

- SikaTack® Panel Fixing Tape

- Sika® PowerClean Aid

Note that rainscreen façade panels are offered separately from the SikaTack® Panel (Bonding) System. Learn more about Petrarch Panels and Steni Panels.

Determining the quantities of components to order

Let us help! Simply provide us with the linear footage of your hats and Z’s (or L’s and T’s), and we’ll let you know how much material you need. Don’t know where to start in calculations? Contact us and we’ll gladly get your project going.

- As a rule of thumb, one roll of SikaTack® Panel Fixing Tape yields about 108 lft

- One Unipack of SikaTack® Panel-50 (adhesive) yields about 59 lft of the single bond line.

- Material waste needs to be considered, based on job conditions and the experience of the installation team.

- Estimates for the consumption of SikaTack® Panel Primer or Sika® Aktivator-205 can only be provided based on project-specific recommendations.

For additional info, contact Sika Corp. at (248)-577-0020 or TSHM@us.sika.com.

SikaTack® Panel System Storage

NOTE: SikaTack® Panel System materials are temperature sensitive.

For general storage in warehouse environments, keep all components above 32° F and below 80° F while in storage.

For temporary storage (at least 24 hours prior to application) at a job site, application temperatures apply – not less than 40° F and not more than 105° F. The ideal temperature range is between 60° F and 85° F for the best application properties.

SikaTack® Panel System product shelf-life values

All components of the SikaTack® Panel system have a shelf life. With proper planning and timely usage, you shouldn’t have any issues.

- SikaTack® Panel-50 (adhesive) – 9 months from production

- SikaTack® Panel Primer – 9 months from production

- Sika® Aktivator-205 – 1 year from production

- SikaTack® Panel Fixing Tape – 2 years from production

- Sika® PowerClean Aid – 2 years from production

Accessories Required for Installation of SikaTack® Panel System

Your installation team should have:

- Unipack application gun

- Rubber gloves & safety glasses

- Fine Scotch Brite (or similar) abrasive pads

- Lint-free paper towel

- Solvent-resistant cups

- Thermometer & humidity gauge

- Shims/jigs for joint spacing

Panels compatible with SikaTack® Panel System

SikaTack® Panel System is compatible with numerous panel types and manufacturers. Sika has performed substrate adhesion testing on many different panels and will test the suitability of the panels used for each specific project.

Have questions about your panels? For additional info, contact Sika Corp. at (248)-577-0020 or TSHM@us.sika.com.

Determine if SikaTack® Panel System will work with project panels

Structural bonding applications are critical applications. Conditions/substrates may vary greatly. The SikaTack® Panel System General Guideline provides some guidance for specific types of surfaces. Customers and applicators must test the suitability of the product for each specific project.

Sika has performed adhesion tests with different panels and framing and will perform tests specific to your job and materials if they haven’t been tested before. Contact Sika at (248)-577-0020 or TSHM@us.sika.com for advice.

SikaTack® Panel System bonding curing time

It takes 7 to 21 days for full cure, with variation based on temperature, humidity, and dew point. Always reference the current Product Data Sheet for complete info.

For additional info, contact Sika Corp. at (248)-577-0020 or TSHM@us.sika.com.

| PRODUCT | CURE / FLASH-OFF TIME |

|---|---|

| SikaTack® Panel-50 | 25 min (skin), 3 weeks fully cured |

| SikaTack® Panel Primer | 10 min - 30 min (ideal), 8 hours max |

| SikaTack® Panel Fixing Tape | N/A |

| Sika® Aktivator-205 | 10 min - 2 hours (ideal) |

| Sika® PowerClean Aid | N/A |

Panel removal after installation

Mistakes happen! Fortunately, a flaw or misplacement is easily remedied.

To remove an existing panel, use a wire saw to cut through the SikaTack® Panel-50 adhesive and SikaTack® Panel Fixing Tape. If the product is not fully cured, you may need to use a solvent to aid in adhesive removal. Be aware not to get adhesive on adjacent panels. After panel removal, scrape off the adhesive and fixing tape if the panel will be reinstalled. Lastly, reapply primer, tape, and adhesive to reinstall the panel.

| PRODUCT | REMOVAL | REAPPLICATION |

|---|---|---|

| SikaTack® Panel-50 | Solvent (wet); Mechanically (cured) | Fresh Material |

| SikaTack® Panel Primer | -- | Repeat Process (once only) |

| SikaTack® Panel Fixing Tape | Manually Peel | Fresh Material |

| Sika® Aktivator-205 | Wipe Off Immediately (wet) | Repeat Process (once only) |

| Sika® PowerClean Aid | N/A | N/A |

Cleaning a panel of SikaTack® bonding components

All panel surfaces should be protected. All pre-treatments and bonding components should be applied at an appropriate distance from the open panel joints. Further, an organized installation process and the use of clean gloves help to prevent contamination of the visible sides of the panel. Even if SikaTack® Panel Fixing Tape could be peeled off some surfaces or uncured SikaTack® Panel-50 (adhesive) could be removed with a solvent, there is always a risk of leaving visible stains. Stains or spilling of SikaTack® Panel Primer or Sika® Aktivator-205 could only be mechanically removed from any surface.

Position of SikaTack® Panel Fixing Tape and SikaTack® Panel-50

- The SikaTack® Panel Fixing Tape and SikaTack® Panel-50 (adhesive) should be applied over the whole length of the vertical sections and parallel to the edges, with appropriate distance from the open panel joint.

- On edge profiles, the SikaTack® Panel Tape should be positioned on the outside edge of the panel that will be placed, creating a barrier to prevent SikaTack® Panel-50 (adhesive) from oozing into the open joint.

- Never encapsulate SikaTack® Panel-50 between two strips of SikaTack® Panel Fixing Tape as the moisture-curing adhesive needs access to air/humidity to ensure its full cure and performance.

For further information, refer to the SikaTack® Panel System General Guideline.

Test the suitability of the product for specific panel surfaces

Since structural bonding applications are critical applications and conditions/substrates may vary greatly, customers and applicators must test the suitability of the product for each specific project. The SikaTack® Panel System General Guideline provides some guidance for specific types of surfaces.

NOTE: Sika has performed adhesion tests with different panels and framing, and will perform tests specific to your job and materials if they haven’t been tested.

Contact Sika at (248)-577-0020 or TSHM@us.sika.com for advice.

Number of installers required for SikaTack® Panel System

The number of installers depends on the size of the panels. Typically, 2 to 3 installers to attach a panel to the desired wall space, but prep and adhesive application can be done by one person.

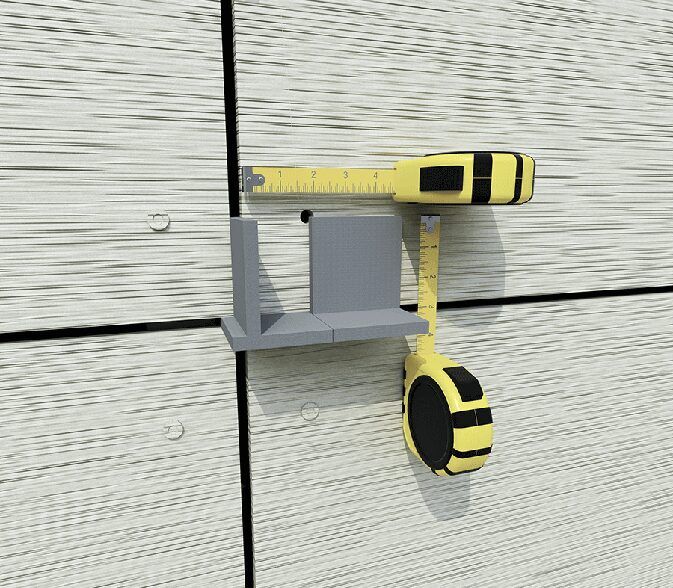

Created perfectly spaced open joints

Want perfectly spaced open joints every time? Panel system installers should check out Joint Jig, a fantastic new spacing device available to ensure perfect open joints every time. No more crooked panels!

SikaTack® Panel System in soffit applications

The SikaTack® Panel System can be designed to carry loads of horizontal underhang and ceiling configurations. However, local requirements, as well as the project or building type-specific limitations, may ask for additional measures for overhead applications.

Note: A soffit panel must not allow any stagnating water or accumulation of dirt on top of it.

Horizontal framing with SikaTack® Panel System

Unfortunately, you cannot. Panels need to be attached to vertical framing when using SikaTack® Panel Systems. Advice on specific applications is available on request from the Technical Department of Sika Industry.

For additional info, contact Sika Corp. at (248)-577-0020 or TSHM@us.sika.com.

SikaTack® Panel System performs in colder climates

The SikaTack® Panel System performs in colder climates and in weather extremes. Thermal dilatation between panel and subframe must be considered, providing an adhesive joint design appropriate for bonded materials and temperature range.

Refer to Product Data Sheet for service temperatures.

Installing SikaTack® Panel System in extreme summer or winter temperatures

The system can be installed in both summer and winter seasons but within a range of 40° and 95° F ambient and surface conditions. Conditions outside of this range might require additional evaluation or specific concepts for product storage, working place set-up, and Quality Control.

Please refer to the Product Data Sheet for exact system properties.

Time to install SikaTack® Panel System versus mechanical face fix

With proper training, SikaTack® Panel System can be installed just as quickly (or quicker) than mechanical face fix where screws or rivets are used, and SikaTack® Panel System outperforms these same panel fixation methods.

Benefits include

- Even stress distribution due to adhesive uniformity (continuous adhesion vs. periodic fasteners)

- Less warping

- Stronger overall bond

- Flex in bonding materials, among other system attributes

How SikaTack® Panel System compares to mechanical fix

SikaTack® Panel System is an engineered system, providing design stress for wind pressure and panel weight, as well as joint movements between sub-framing and panel. Based on project-specific system verification, STPS provides optimal safety and durability. Elastic joint properties help to reduce panel distortion and peak stress. An appropriate design of the bonding components might also allow optimization of panel thickness and result in additional savings of material, weight, and labor costs.

SikaTack® Panel System warranty

Yes, Sika offers a warranty program. The warranty requirements are based on project conditions and the required warranty term. The warranty request must be submitted to Sika before system installation.

Please contact Omnis during the design phase and prior to the project’s start.

SikaTack® Panel System installation training

Representatives from Sika and Omnis will come to your shop or job site and train your team on how to install panels with SikaTack® Panel System. Training sessions are typically half-day visits. Virtual training is also available.

Contact us to schedule training for your team!

Your team should be knowledgeable in rainscreen panel installation. That’s where we can help! Sika’s jobsite support and applicator training will help your team to become experts in using SikaTack® Panel System.

SikaTack® Panel System qualifies as a Green Building Material

Sika provides reports and certificates for SikaTack® Panel-50 such as Environmental Product Declaration (EPD), a GreenCircle Certificate, and an emissions report (according to CDPH Standard Method Version 1.2), qualifying for “Green Building,” “Well,” or “LEED” credits.

Thank you for your interest in SikaTack® Panel System

Omnis Panels is proud to be the exclusive US distributor of the adhesive rainscreen attachment system SikaTack® Panel System.

Mark precisely where the first panel must be bonded on the substructure, or use a reference fixed on the substructure. Make notes for your record with all relevant information. Ambient Temperature 40 – 95°F

Mark precisely where the first panel must be bonded on the substructure, or use a reference fixed on the substructure. Make notes for your record with all relevant information. Ambient Temperature 40 – 95°F